Safety Precautions

Always wear safety glasses and gloves when operating the Bostitch SB-1664FN. Ensure proper ventilation and avoid loose clothing. Disconnect the air supply before servicing or adjusting the tool. Never point the nailer at people or animals. Keep children away from the work area. Use the trigger lock to prevent accidental firing. Store the tool in a dry‚ secure location. Follow all safety warnings in the manual to avoid injuries and damage.

- Avoid overreaching or using the tool in unsafe conditions.

- Keep the work area clean and well-lit.

- Never modify the tool or use unauthorized parts.

1.1 General Safety Guidelines

Before operating the Bostitch SB-1664FN‚ ensure you wear safety glasses and gloves to protect against debris. Keep loose clothing and long hair tied back to avoid entanglement. Always maintain a clean‚ well-lit workspace to prevent accidents. Never point the tool at people or animals‚ and ensure bystanders are at a safe distance. Use the trigger lock to prevent unintended firing when not in use. Store the nailer in a dry‚ secure location out of reach of children. Follow all safety warnings in the manual to minimize risks. Proper ventilation is essential to avoid inhaling dust or fumes. Avoid overreaching or using the tool in unstable conditions. Regularly inspect the tool for damage or wear before use.

- Ensure the work area is free from clutter and tripping hazards.

- Never modify the tool or use unauthorized accessories.

1.2 Handling and Storage Tips

Handle the Bostitch SB-1664FN with care to prevent damage. Store it in a dry‚ cool place away from direct sunlight to maintain performance. Use the provided case to protect the tool during transportation. Keep the nailer out of reach of children and unauthorized users. Regularly clean the tool to remove dirt and debris‚ ensuring optimal functionality; When not in use‚ disconnect the air supply and engage the trigger lock. Avoid storing the tool in humid or extreme temperature environments‚ as this can cause rust or malfunctions. Always check for wear or damage before storing. Proper handling and storage extend the tool’s lifespan and ensure safety.

- Store the tool in an upright position to prevent oil leakage.

- Keep the storage area well-ventilated to avoid condensation.

1.3 Emergency Procedures

In case of an emergency‚ disconnect the air supply immediately and engage the trigger lock. If a nail jam occurs‚ do not attempt to clear it while the tool is pressurized. Always follow proper jam-clearing procedures outlined in the manual. If the tool malfunctions‚ stop use and contact an authorized service center. Never attempt to repair the tool yourself unless specified in the manual. Keep the work area clear and ensure proper ventilation. In case of accidental firing‚ seek medical attention if necessary. Always prioritize safety and follow emergency protocols to prevent further incidents.

- Disconnect the air supply before addressing any issue.

- Never use the tool if it is damaged or malfunctioning.

- Contact Bostitch customer support for professional assistance.

1.4 Personal Protective Equipment (PPE)

Wear safety glasses or goggles to protect your eyes from debris. Use gloves to maintain a secure grip and prevent hand injuries. Steel-toe boots are recommended to safeguard feet from falling objects. A dust mask is advisable to avoid inhaling particles during operation. Ensure all loose clothing and jewelry are secured to prevent entanglement with moving parts. Hearing protection may be necessary in noisy environments. Always use PPE as specified in the Bostitch SB-1664FN manual to minimize risks while operating the tool.

- Safety glasses or goggles for eye protection.

- Gloves for grip and hand safety.

- Steel-toe boots for foot protection.

- Dust mask for respiratory safety.

Tool Overview

The Bostitch SB-1664FN is a 16-gauge straight finish nailer designed for precision and durability. It is ideal for woodworking‚ cabinetry‚ and finish carpentry applications‚ offering versatility and reliability.

- 16-gauge straight finish nailer.

- Suitable for woodworking and carpentry.

- Durable and reliable performance.

The Bostitch SB-1664FN is a 16-gauge straight finish nailer designed for precision and durability in woodworking‚ cabinetry‚ and finish carpentry. It offers a lightweight yet robust build‚ making it ideal for professional contractors and DIY enthusiasts alike. The tool features a straight magazine design‚ allowing for easy loading of 1-inch to 2-1/2-inch nails. Its ergonomic grip ensures comfortable handling during extended use. The SB-1664FN is known for its consistent performance‚ delivering accurate nail placement with minimal recoil. With its versatile design and reliable operation‚ this nailer is a valuable addition to any toolkit.

- 16-gauge straight finish nailer.

- Lightweight and durable construction.

- Ergonomic design for comfort.

- Compatible with 1″ to 2-1/2″ nails.

2.2 Technical Specifications

The Bostitch SB-1664FN is a 16-gauge straight finish nailer designed for precision and versatility. It accepts 1″ to 2-1/2″ finish nails‚ making it suitable for a variety of woodworking applications. The tool operates on compressed air‚ requiring a pressure range of 70-120 PSI. It features a durable aluminum body and a magnesium housing for lightweight durability. The SB-1664FN includes a 360-degree adjustable exhaust and a trigger lockout for safety. The magazine capacity is approximately 100-120 nails‚ depending on nail length. It weighs around 4.5 lbs‚ ensuring easy portability. The tool is backed by a 7-year limited warranty‚ reflecting its robust construction and reliability.

- 16-gauge straight finish nailer.

- Nail length: 1″ to 2-1/2″.

2.3 Features and Benefits

The Bostitch SB-1664FN offers a range of innovative features designed to enhance productivity and user experience. Its 16-gauge straight finish nailer is ideal for trim work‚ cabinetry‚ and furniture assembly‚ providing precise control over nail placement. The tool’s adjustable depth control allows for consistent nail depth in various materials‚ ensuring professional results. The magnesium housing and aluminum components contribute to a lightweight yet durable design‚ reducing fatigue during extended use. The 360-degree exhaust port minimizes air debris‚ keeping the work area clean. Additionally‚ the trigger lockout mechanism enhances safety by preventing accidental firing. These features make the SB-1664FN a reliable choice for professionals and DIYers alike‚ delivering efficiency and precision in every project.

- Lightweight magnesium housing for reduced fatigue.

- Adjustable depth control for consistent results.

- 360-degree exhaust for a cleaner workspace.

Installation and Setup

Begin by unpacking and inspecting the Bostitch SB-1664FN for any damage. Connect the tool to a clean‚ dry air supply‚ ensuring proper pressure settings. Next‚ follow the initial setup guide in the manual to configure the tool for your specific needs. Always disconnect the air supply before making adjustments or performing maintenance to ensure safety and prevent accidental activation.

- Inspect all components for damage before use.

- Connect to a clean‚ dry air supply for optimal performance.

- Refer to the manual for initial setup instructions.

3.1 Unpacking and Inspection

When unpacking the Bostitch SB-1664FN‚ carefully remove all components from the box. Inspect the tool for any visible damage or wear. Check the nailer‚ air hose‚ and accessories for completeness. Ensure all parts are free from defects or scratches. If any damage is found‚ contact the manufacturer immediately. Familiarize yourself with the tool’s features and components before proceeding with setup. Proper inspection ensures safe and efficient operation. Always refer to the manual for specific unpacking guidelines and part identification.

- Examine the tool for any signs of damage.

- Verify the completeness of included accessories.

- Contact support if any issues are found.

3.2 Air Supply and Connections

Connect the Bostitch SB-1664FN to a clean‚ dry air supply with a pressure range of 80-120 PSI. Use a high-quality air hose with proper threading to avoid leaks. Ensure the air supply is free from oil and moisture to prevent tool damage. Before connecting‚ drain the air tank and check for any blockages. Securely attach the air hose to the tool’s inlet port‚ ensuring it is tightly fitted. Test the connection by pulling the trigger slightly to check for leaks. Always disconnect the air supply when performing maintenance or adjustments. Proper air supply setup ensures optimal performance and safety.

- Use a clean‚ dry air source between 80-120 PSI.

- Inspect the air hose for damage before use.

- Ensure all connections are secure and leak-free.

3.3 Initial Tool Setup

Before first use‚ inspect the Bostitch SB-1664FN for damage or wear. Ensure all parts are included and properly assembled. Install the non-marking pads to protect work surfaces. Set the depth adjustment using the Dial-A-Depth control to achieve the desired fastener depth. Load the nails according to the manufacturer’s instructions; Connect the air supply and test the tool at a low pressure to ensure proper operation. Adjust the trigger lockout and fastener control as needed. Refer to the manual for specific setup steps to ensure optimal performance and safety.

- Inspect the tool for damage or wear.

- Assemble and install any optional accessories.

- Test the tool at low pressure before full operation.

Operating Instructions

Operate the Bostitch SB-1664FN by loading nails‚ adjusting fastener control‚ and using the trigger lockout. Always maintain control and follow safety guidelines for efficient use.

- Load nails correctly to ensure proper function.

- Adjust settings for precise fastening results.

- Use the trigger lock to prevent accidental firing.

4.1 Loading Nails

To load nails into the Bostitch SB-1664FN‚ start by pulling the follower back until it latches. This ensures the nails are securely held in place. Next‚ insert the nails into the magazine‚ aligning them correctly to prevent bending or overlapping. Make sure to use the correct type and size of nails as specified in the manual. Once loaded‚ gently release the follower to advance to the first nail. Avoid overloading the magazine‚ as this can cause jams. Always keep your fingers away from the trigger during loading and ensure the muzzle is pointed in a safe direction. If nails don’t feed properly‚ check for alignment issues or blockages. Test the tool with a few nails before starting a project to ensure smooth operation.

- Pull the follower back until it latches.

- Insert nails correctly to avoid bending.

- Use the recommended nail type and size.

- Release the follower gently after loading.

- Avoid overloading the magazine.

- Test the tool before starting a project.

4.2 Adjusting Fastener Control

Adjusting the fastener control on the Bostitch SB-1664FN ensures proper nail depth in various materials. To adjust‚ first disconnect the air supply for safety. Locate the Dial-A-Depth control knob on the tool’s nose. Turn the knob clockwise for deeper fastening or counterclockwise for shallower depth. Use the reference marks on the knob to guide your setting. Test the depth on scrap material before starting your project. Fine-tune the adjustment as needed to achieve the desired results. Always refer to the manual for specific recommendations based on material thickness and type.

- Disconnect air supply before adjusting.

- Use the Dial-A-Depth knob to set nail depth.

- Test adjustments on scrap material.

4.3 Trigger Lockout Control

The Trigger Lockout Control on the Bostitch SB-1664FN is a safety feature designed to prevent accidental firing. Engage the lock by pulling it back toward the handle. To disengage‚ squeeze the trigger while moving the lock forward. Always ensure the lock is disengaged before use. Keep the tool pointed away from people and animals. Use the lock when loading nails or adjusting settings to enhance safety. Regularly inspect the lock mechanism for proper function. Follow the manual’s guidelines for maintaining this feature. Proper use of the Trigger Lockout Control is essential for safe and efficient operation.

- Engage the lock when not firing to prevent accidents.

- Disengage by squeezing the trigger and moving the lock forward.

- Always point the tool away from people and animals.

Maintenance and Care

Regularly clean and lubricate the Bostitch SB-1664FN to ensure optimal performance. Inspect for wear and tear‚ replacing worn parts promptly. Refer to the manual for specific maintenance tasks and schedules to maintain tool longevity and safety.

- Clean the tool after each use to prevent debris buildup.

- Use recommended lubricants for moving parts.

- Store the tool in a dry‚ secure location.

5.1 Daily Maintenance Routine

Perform a daily check of the Bostitch SB-1664FN to ensure smooth operation. Start by cleaning the tool with a soft cloth‚ removing dirt and debris. Inspect the nail magazine and feeder for proper alignment and damage. Lubricate moving parts with a few drops of air tool oil to reduce friction. Check the air filter and ensure it’s clean to maintain consistent air flow. Test the trigger lockout to confirm it’s functioning correctly. Store the tool in a dry‚ secure location after use. Regular cleaning and lubrication help prevent jams and extend tool life. Always follow the maintenance schedule outlined in the manual for optimal performance.

5.2 Lubrication and Cleaning

Regular lubrication and cleaning are essential for maintaining the Bostitch SB-1664FN. Apply a few drops of air tool oil to moving parts daily to reduce wear and ensure smooth operation. Use a soft cloth to wipe down the tool‚ removing dirt and debris; Clean the nail magazine and feeder regularly to prevent jams. Avoid using harsh chemicals or abrasive materials that could damage the finish. Lubricate the piston and cylinder after every 8 hours of use for optimal performance. Store the tool in a dry‚ clean environment to prevent rust. Regular cleaning and lubrication help extend the tool’s lifespan and maintain efficiency.

- Use only recommended air tool oil for lubrication.

- Avoid over-lubricating to prevent residue buildup.

5.3 Regular Servicing Schedule

Regular servicing is crucial to maintain the performance and longevity of the Bostitch SB-1664FN. Schedule professional servicing every 3 to 6 months or after 50‚000 cycles. Check the piston‚ cylinder‚ and valve for wear and replace as needed. Inspect the feeder and magazine for alignment issues. Clean or replace the air filter every 1‚000 hours of use. Lubricate all moving parts during servicing to ensure smooth operation. Replace the O-rings and seals annually or as recommended. Follow the maintenance manual for specific guidelines. Regular servicing prevents downtime and ensures consistent performance.

- Inspect for wear and tear during each servicing session.

- Replace worn parts promptly to avoid tool malfunction.

Troubleshooting Common Issues

Troubleshoot the Bostitch SB-1664FN by addressing jams‚ depth issues‚ and air pressure problems. Clear nail jams by disconnecting the air supply and releasing the pusher. Adjust depth control for proper nail setting. Check air pressure settings and ensure proper connections to resolve operating issues. Refer to the manual for detailed procedures to maintain optimal performance and prevent tool malfunction.

- Resolve jams promptly to avoid further damage.

- Adjust settings carefully for consistent results.

6.1 Jamming and Clearing Procedures

To clear a jam in the Bostitch SB-1664FN‚ follow these steps:

Disconnect the air supply to ensure the tool is safe to handle.

Release the pusher mechanism to stop applying pressure on the nail sticks.

Remove the jammed nails by carefully pulling them out or using pliers if necessary.

Check for obstructions in the magazine or nosepiece and clean them thoroughly.

Reassemble the tool and test it with a few nails to ensure proper function.

Regular maintenance‚ such as lubricating moving parts and cleaning the tool‚ can help prevent jams. Always refer to the manual for detailed diagrams and instructions. Proper care ensures optimal performance and extends the tool’s lifespan.

- Act quickly to clear jams to avoid further issues.

- Use the correct nail size and type for smooth operation.

6.2 Depth Adjustment Problems

If the Bostitch SB-1664FN isn’t driving nails to the desired depth‚ check the Dial-A-Depth control. Ensure it’s clean and free from debris. Verify that the correct nail size is being used. If issues persist‚ recalibrate the control by following the manual’s instructions. Regularly lubricate the tool to maintain smooth operation. Always use nails compatible with the SB-1664FN to avoid depth inconsistencies. For persistent problems‚ consult the troubleshooting guide or contact customer support.

- Keep the Dial-A-Depth control clean and well-maintained.

- Use the correct nail size and type for consistent results.

6.3 Air Pressure Issues

If the Bostitch SB-1664FN isn’t functioning properly due to air pressure issues‚ ensure the compressor is set to the recommended pressure range (80-120 PSI). Check for air leaks in the hose or connections. Disconnect the tool from the air supply before adjusting settings. Verify that the air filter is clean and free from blockages. If the issue persists‚ inspect the regulator and ensure it’s properly calibrated. Always refer to the manual for specific pressure recommendations. Maintaining consistent air pressure is crucial for optimal performance and nail placement accuracy.

- Check the air hose and connections for leaks or damage.

- Ensure the compressor output matches the tool’s requirements.

Parts List and Diagrams

Refer to the exploded view diagram for detailed parts identification. The manual provides an itemized list of components with descriptions‚ ensuring easy ordering of replacement parts.

- Use the diagrams to locate and identify tool components accurately.

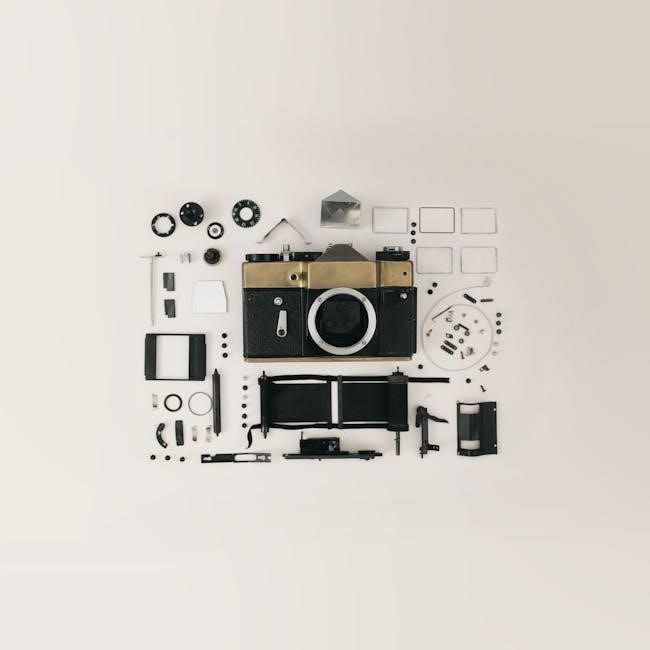

7.1 Exploded View of the Tool

The exploded view diagram provides a detailed visual breakdown of the Bostitch SB-1664FN’s components. This diagram is essential for identifying and locating parts‚ such as the magazine‚ trigger‚ and valve assembly. Each component is numbered and labeled‚ corresponding to the parts list in the manual. Use this diagram to understand how the tool is assembled and to identify specific parts that may need replacement or maintenance. Cross-reference the exploded view with the parts list to ensure accurate ordering of replacement components. The diagram also helps in visualizing the tool’s internal structure‚ making it easier to perform repairs and servicing. Always refer to the official manual for the most accurate and up-to-date exploded view.

- Use the diagram to identify parts by their numerical labels.

- Refer to the parts list for descriptions and part numbers.

- Ensure all repairs are done with genuine Bostitch parts for optimal performance.

7.2 Parts Identification and Description

The Bostitch SB-1664FN manual provides detailed descriptions of each part‚ ensuring proper identification for maintenance and repairs. Key components include the magazine assembly‚ trigger mechanism‚ and valve system. The magazine holds the nails and is designed for smooth loading. The trigger mechanism controls the firing action‚ while the valve assembly regulates air flow. Other critical parts include the piston‚ driver blade‚ and fastener control dial. Each part is numbered and described in the manual‚ along with its function and location. This section helps users understand how each component contributes to the tool’s operation. Always refer to the official parts list for accurate identification and ordering of replacement parts.

- Magazine assembly: Holds and feeds nails into the tool.

- Trigger mechanism: Activates the nailing function.

- Valve assembly: Controls air pressure and flow.

Warranty and Support

The Bostitch SB-1664FN is backed by a comprehensive manufacturer warranty. For support‚ contact Bostitch customer service or visit authorized service centers. Warranty details and support options are outlined in the manual.

- Manufacturer warranty covers defects in materials and workmanship.

- Authorized service centers provide professional tool repair.

- Customer support is available for troubleshooting and assistance.

8.1 Manufacturer Warranty Details

The Bostitch SB-1664FN is covered by a limited warranty from Stanley Black & Decker. This warranty protects against defects in materials and workmanship for a specified period. The warranty duration varies depending on the product and usage conditions‚ typically covering one to five years for most components. It is essential to review the warranty terms provided in the manual or on the manufacturer’s website for exact details. Proper registration and maintenance of the tool are often required to maintain warranty coverage. Any damage resulting from misuse‚ improper maintenance‚ or unauthorized modifications may void the warranty. For specific inquiries‚ contact Bostitch customer support or refer to the official documentation.

8.2 Customer Support Contacts

Bostitch provides dedicated customer support to assist with inquiries‚ troubleshooting‚ and repair services for the SB-1664FN. For immediate assistance‚ contact Bostitch customer service at 1-800-556-6696. Support is available 24/7 to address any concerns. Additionally‚ users can email customer support at customer.service@bostitch.com for non-urgent matters. Visit the official Bostitch website at www.bostitch.com for detailed support resources‚ including FAQs‚ manuals‚ and service center locations. Representatives are trained to help with tool maintenance‚ warranty claims‚ and operational guidance‚ ensuring optimal performance and user satisfaction.

- Phone: 1-800-556-6696 (24/7 support)

- Email: customer.service@bostitch.com

- Website: www.bostitch.com

8.3 Authorized Service Centers

Bostitch SB-1664FN users can access professional repair services through the extensive network of Bostitch Authorized Service Centers. These centers are equipped with factory-trained technicians and genuine parts to ensure high-quality repairs. To locate the nearest service center‚ visit the Bostitch website or contact customer support. Additionally‚ Bostitch Factory Service Centers offer expedited repair options for critical tool maintenance. All authorized centers adhere to strict quality standards‚ guaranteeing reliable and efficient service for your SB-1664FN.

- Over 1800 authorized service locations worldwide.

- Factory-trained technicians ensure expert repairs.

- Genuine Bostitch parts used for all services.

Best Practices

Regularly maintain the SB-1664FN to ensure optimal performance. Use genuine Bostitch parts and follow the manual for adjustments. Keep the tool clean and lubricated. Always store it in a dry‚ secure location.

- Perform daily inspections before use.

- Use the correct nail size for the job.

- Follow environmental guidelines for disposal.

9.1 Optimal Tool Usage

For optimal performance of the Bostitch SB-1664FN‚ always use the correct 16-gauge straight finish nails. Ensure the tool is properly lubricated and adjusted before use. Maintain consistent air pressure as specified in the manual. Avoid overloading the magazine‚ and keep the tool clean. Use the depth adjustment feature to ensure nails are driven to the correct depth. Work in a well-lit‚ stable environment‚ and avoid using the tool in extreme temperatures. Regularly inspect the tool for wear and tear‚ and refer to the manual for specific settings for different materials. Proper usage will extend the tool’s lifespan and ensure professional results.

- Always follow the manual’s recommendations for nail size and type.

- Use the trigger lock when not in use to prevent accidents.

- Keep the work area clean to avoid debris-related issues.

9.2 Environmental Considerations

Proper disposal and recycling of worn or damaged parts are essential for environmental protection. Use Bostitch’s recycling program for responsible disposal of tools and packaging. Always follow local regulations for waste management. Minimize waste by using nails of the correct size and type‚ reducing overuse of materials. Regular maintenance prevents oil leaks and extends tool life‚ reducing the need for frequent replacements. Store the tool in a dry‚ secure location to prevent damage and corrosion. Avoid using excessive air pressure‚ as it can increase energy consumption. By following these guidelines‚ you contribute to a more sustainable work environment.

- Recycle packaging materials whenever possible.

- Avoid disposing of tools in regular trash.

- Participate in Bostitch’s environmental programs.

FAQs

- What nail size does the SB-1664FN use? It uses 16-gauge straight finish nails.

- How do I clear a jam? Disconnect air supply‚ release the pusher‚ and remove jammed nails.

- Can I adjust the nail depth? Yes‚ use the Dial-A-Depth control for precise depth adjustment.

10.1 Common Questions

Users often ask about the Bostitch SB-1664FN’s compatibility with different nail sizes. It accepts 16-gauge straight finish nails‚ ensuring versatility for various projects. Another common query is about resolving jams. To clear a jam‚ disconnect the air supply‚ release the pusher‚ and carefully remove the obstructed nails. Adjusting the depth of nail drive is also a frequent question. The Dial-A-Depth control allows precise adjustment for consistent results. Additionally‚ users inquire about the tool’s maintenance. Regular lubrication and cleaning are essential to maintain optimal performance. For troubleshooting‚ refer to the operation manual or contact customer support.

- What nail size does the SB-1664FN use?

- How to clear a nail jam?

- Can the nail depth be adjusted?

10.2 User Tips and Tricks

For optimal performance of the Bostitch SB-1664FN‚ ensure regular lubrication of moving parts to prevent wear. Always test the nail depth on scrap material before starting your project. To avoid nail jams‚ use high-quality nails and keep the magazine fully loaded. Store the tool in a dry place to prevent rust. For consistent results‚ adjust the Dial-A-Depth control carefully. Clean the tool after each use to maintain efficiency. Use the trigger lock when not in use to ensure safety. Refer to the manual for specific maintenance schedules. Proper care extends the tool’s lifespan and ensures reliable operation.

- Test nail depth on scrap material first.

- Use high-quality nails to avoid jams.

- Clean the tool regularly for optimal performance.